We specialise in advanced manufacturing—from engineering design and quality testing to digital transformation—connecting you with the right equipment, expertise, and networks to accelerate your manufacturing.

What will the AMRF offer?

- A single destination for high-value manufacturing solutions, from design to manufacturing, to process validation

- Increased value for your investment, and increased speed to market, via affordable access to world-class technology, expertise, training, and networks

- An expert team of engineers, who will provide trustworthy and independent advice to de-risk investment in capability development, and provide application guidance in manufacturing technologies from prototyping to large-scale production

- Practical, hands-on staff training, to accelerate adoption of technology and support the scale-up of your business

Read more about our full range of capabilities below.

Our capabilities

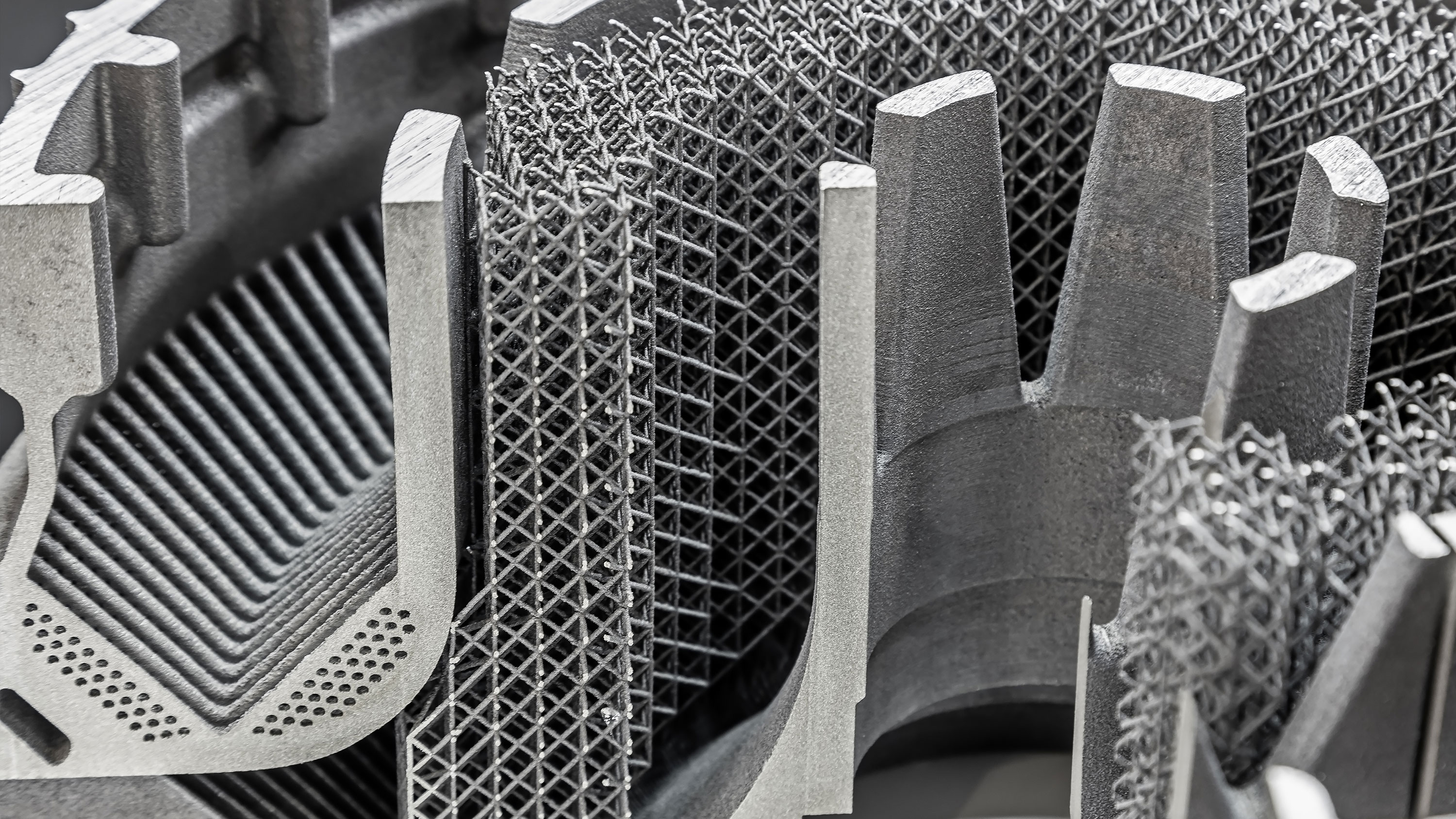

- Laser-Powder Bed Fusion (L-PBF)

- Industry-specific qualification methodologies

- Large-scale additive manufacturing (polymers)

- Post-Processing and Non-Destructive-Evaluation

- Rapid tooling manufacture for hand layup

- Compression moulding for high throughput

- Filament winding combined with Automated Fibre Placement (AFP)

- Automated pattern making and ply cutting

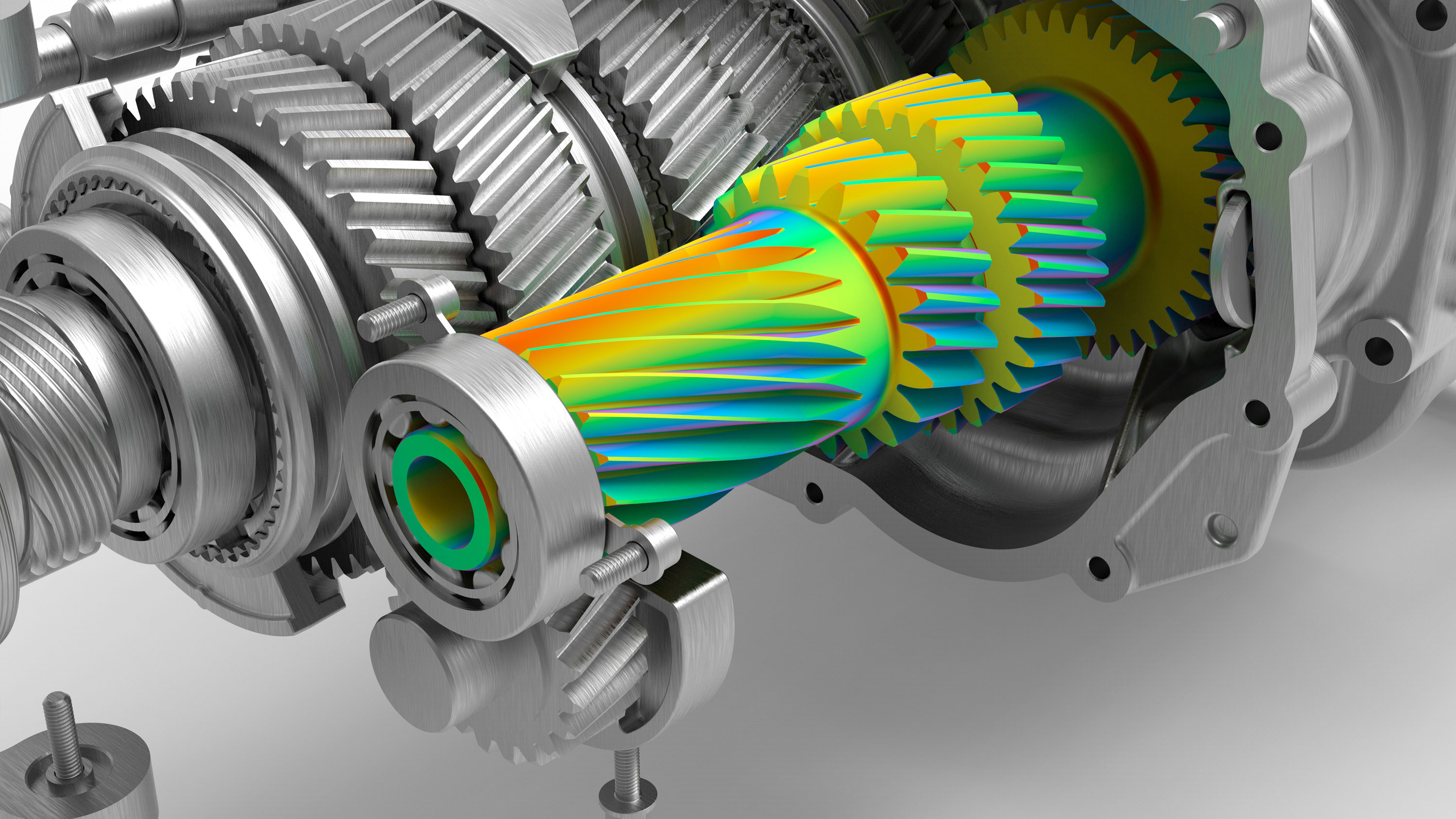

- Visualisation, simulation & modelling of factory systems

- Manufacturing systems integration & optimisation

- Data acquisition, IIoT, machine learning & analytics

- Design for manufacture processes

- Design/Redesign for additive manufacture

- Technical drawing creation

- Tooling and fixture design

- Process control systems

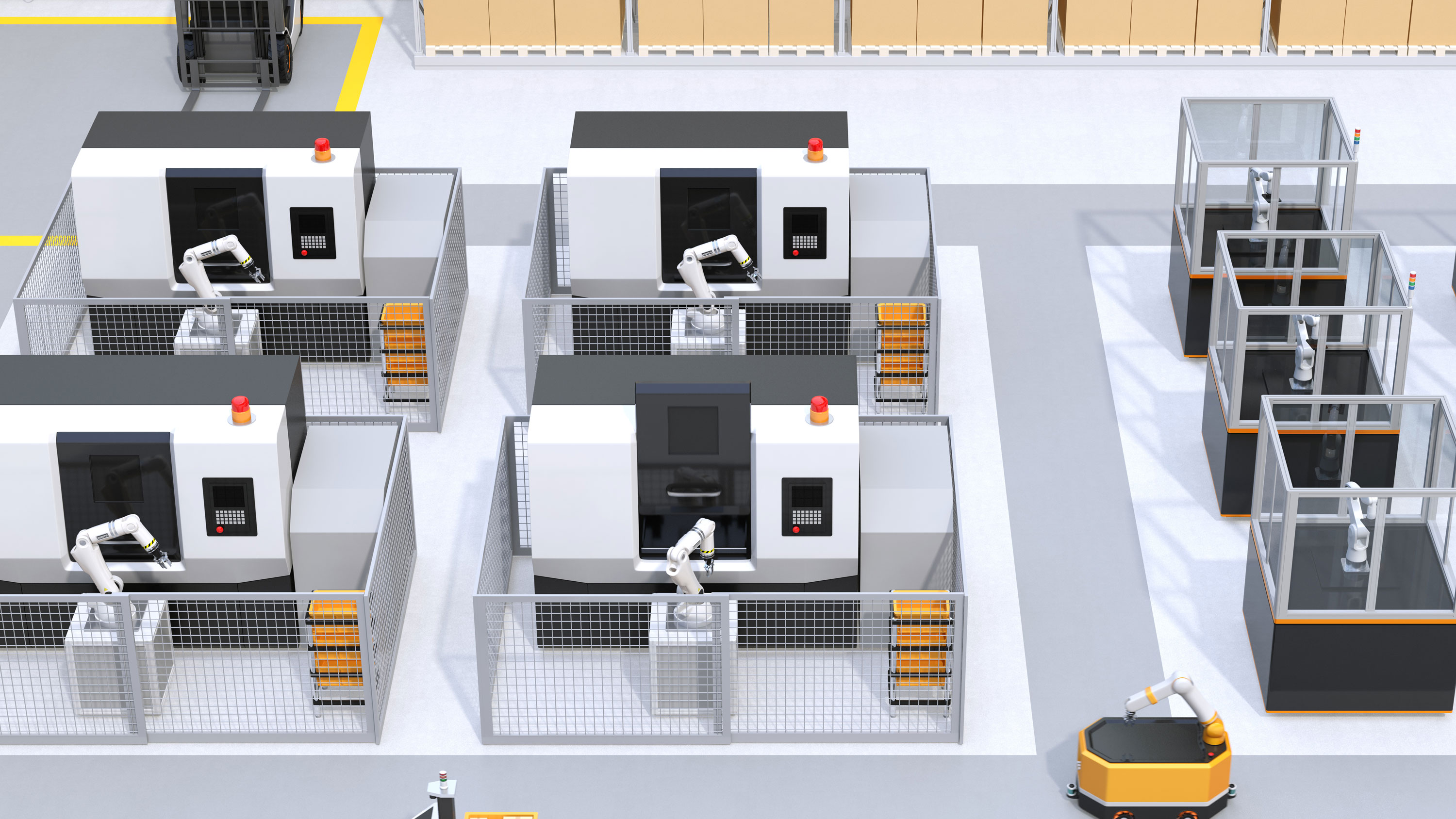

- Flexible multi-process automation

- Cobotics and AGVs/AMRs

- Lights-out manufacturing demonstrator

- Data acquisition, IIoT, machine learning & analytics

- Industrial X-Ray - CT Scanning

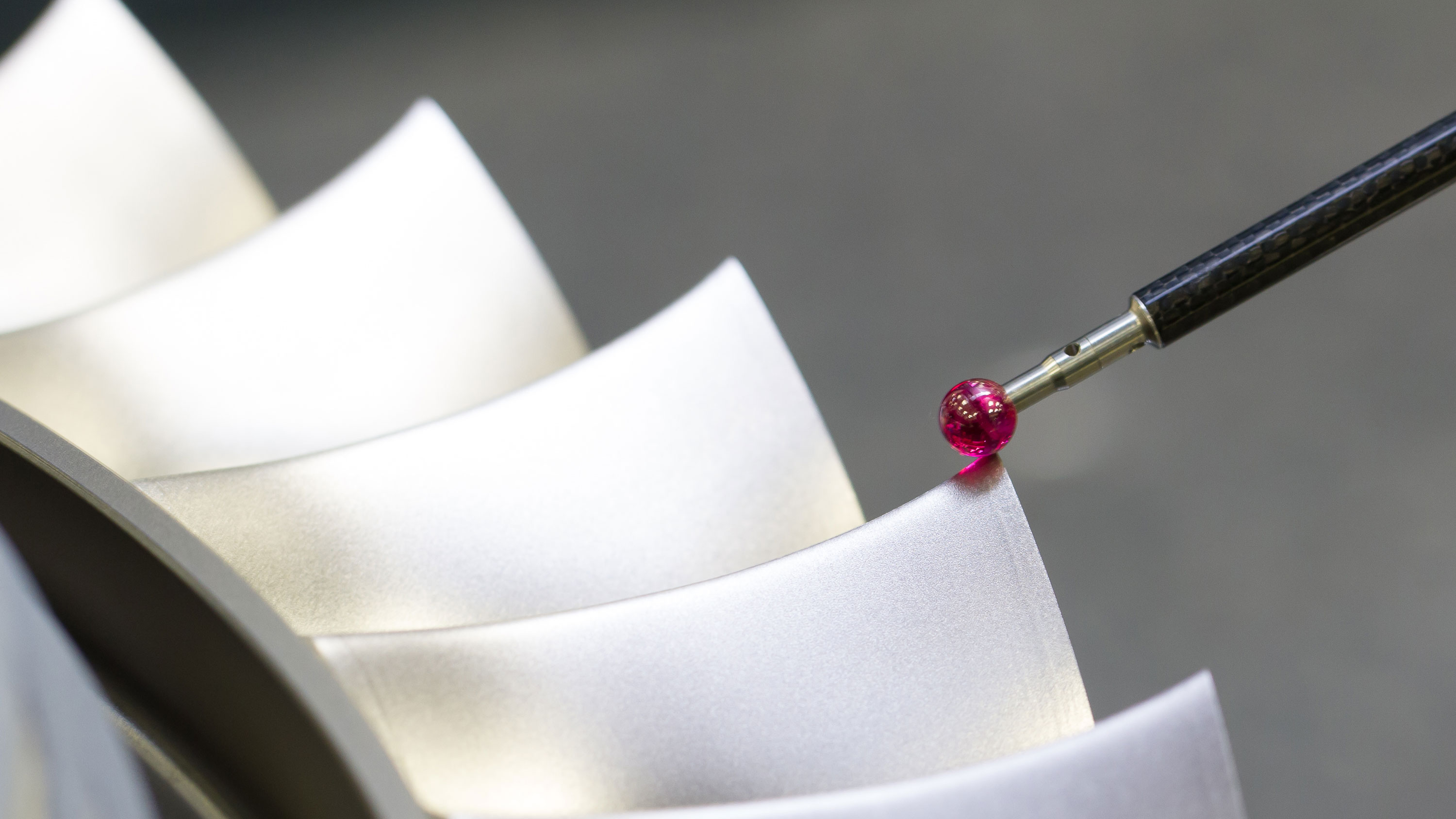

- Single-micron inspection with laser surface scanning

- Confocal / Digital Microscopy

- Coordinate Measuring Machine (CMM)

- Precision Inspection / Gaging

- Automated machine loading capability

- Multi-axis machines for ultimate precision

- Integrated grinding and technology cycles for high value components

- World class CAM program and simulation

- Optimized for performance and quality

- Full process life cycle traceability

- Materials testing and verification

- Specification and requirements management

- Product Data/Lifecycle Management

- Material/Assembly Failure Analysis